Pulling out threads from fabric is addictive. I made a lot of samples because I couldn’t stop. This post shares some with you!

5.1: Withdrawing threads in different directions

5.2: Withdrawing threads from scrim – it’s jolly tricky! But very satisfying,

5.3: Withdrawing threads from scrim – it gets quite delicate.

5.4: Withdrawing threads from scrim.

5.5: Withdrawing threads from scrim.

5.6: Withdrawing thread from scrim and then displacing some threads

5.7: Close up of displaced threads.

5.8: Displaced threads without fulling withdrawing any (using linen). This was jolly satisfying, like ‘blurring’ the fabric.

5.9: On one side I pulled threads into little loops and on the other side I (a) pulled threads out fully and wove some back in the voids, and (b) I didn’t pull the threads out completely and wove them back in.

5.10: Close up of a little patch of loose weave that was created from pulling the threads into loops.

5.11: Threads fully withdrawn and then replaced with bundles of thread from a different piece of fabric contrasting in colour.

5.12: Threads withdrawn and some woven back in.

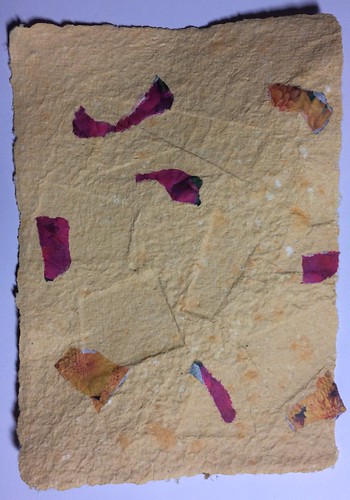

5.13: Weave threads pulled from a different piece of fabric (which was coloured with blackberries) and woven into a piece of linen which was dyed with nasturtium flowers.

5.14: Weave threads from different pieces of fabric added to the grid with withdrawn threads looped and tied into a knot.

5.15: Threads from different fabric woven around a grid.

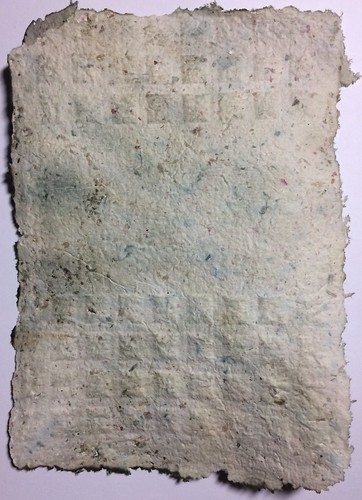

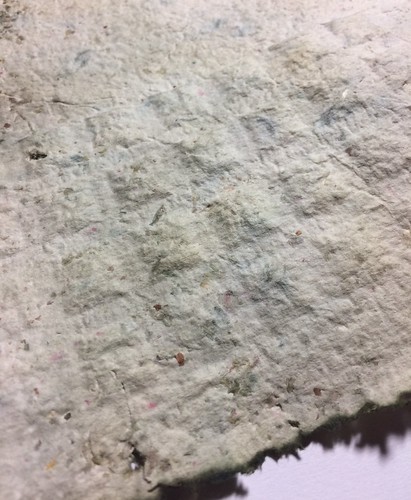

5.16: Threads withdrawn from jute scrim. The fabric already has a loose weave so it is quite delicate

5.17: Some threads pulled from jute scrim with the remaining ones being moved around.

5.18: Threads withdrawn and woven back in at different angles.

5.19: Threads withdrawn and then woven back in in a pattern

5.20: Threads withdrawn and woven back in a haphazard fashion.

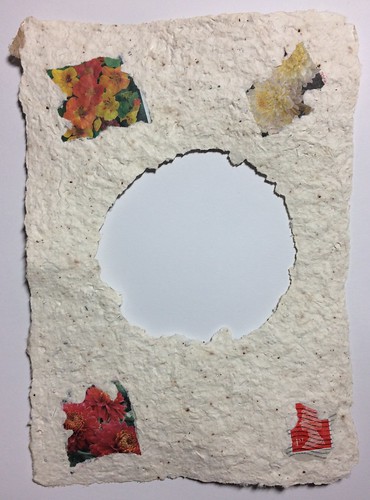

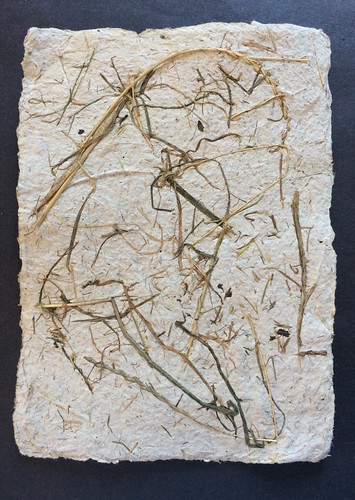

I couldn’t resist and all of the jute samples ended up with paper pulp on them… results to be shared in a later post!